Level Sensors

Whether for continuous level measurement, point level measurement or both – SICK offers a wide range of solutions for process engineering, storage, and protection. Based on the installation situation, medium properties, and ambient conditions, SICK provides sensors that ensure efficient processes. As the provider of one of the broadest technology portfolios, SICK brings its knowledge to the forefront.

LBR SicWave

Simply brilliant – level measurement in bulk materials with 80 GHz radar

- 80 GHz free-space radar with various antennas

- Measuring range: up to 120 m

- Process temperature: −40 °C … +200 °C

- Process pressure: −1 bar … 20 bar

- Process connection: thread, flange, special brackets

- Housing: plastic (IP66 / IP67) or aluminum (IP66 / IP68)

- With or without display and WPAN

- Certificates: Ex d, Ex ia, Ex ta

LFP Inox

The clean solution

- Level measurement in hygienic applications

- Rod probe can be cut to length manually up to 4,000 mm long with Ra ≤ 0.8 µm (optionally with Ra ≤ 0.4 µm)

- Process temperature up to 180 °C, process pressure up to 16 bar

- CIP/SIP-resistant

- High enclosure rating: IP 67 and IP 69, autoclavable

- Interchangeable hygienic process connections

- 3 in 1: combines display, analog output, and binary output

- Remote amplifier with process connection

- IO-Link 1.1

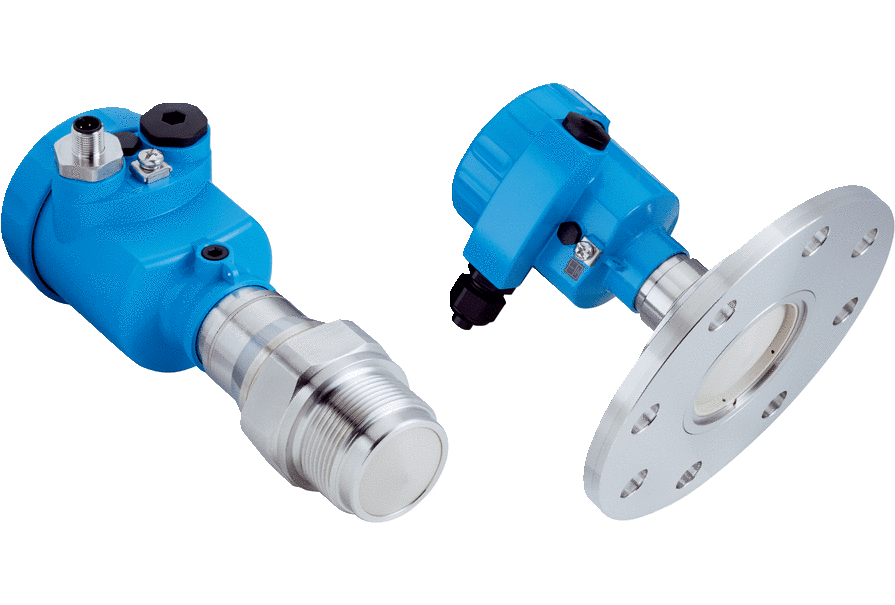

LFR SicWave

Simply brilliant – level measurement in liquids with 80 GHz radar

- 80 GHz free-space radar with various antennas

- Measuring range: up to 30 m

- Process temperature: −196 °C … +200 °C

- Process pressure: −1 bar … 25 bar

- Process connection: thread, flange, clamp

- Housing: plastic (IP66 / IP67), aluminum (IP66 / IP68) or stainless steel (IP69)

- With or without display and WPAN

- Certificates: Ex d and Ex ia, WHG, shipbuilding

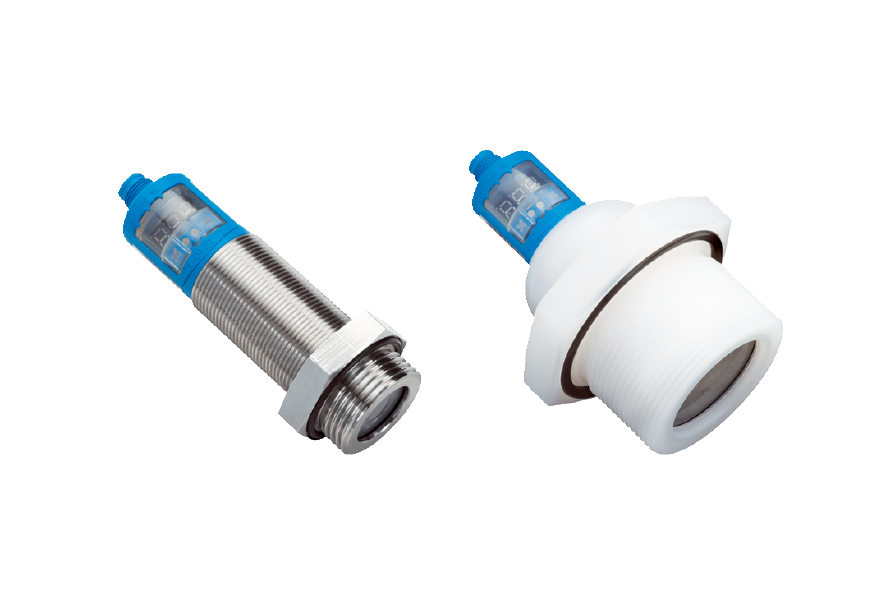

UP56 Pure

Pure reliability

- Ultrasonic level sensor with very high chemical resistance

- Non-contact measurement in immersion pipe of up to 1,500 mm

- PTFE-coated membrane and GF D40 process connection made of PTFE

- Pressure resistant up to 6 bar, temperature resistant up to 85°C

- Different sizes available

- Analog output selectable between 4 mA to 20 mA and 0 V to 10 V

- Switching output for monitoring the maximum and minimum limit

LFP Cubic

Flexible up to the probe tip

- Level sensor for liquids

- No mechanical moving parts

- Interchangeable rod probe which can be cut to lengths between 200 mm and 2,000 mm (cable probe up to 4,000 mm)

- Resistant to deposit formation

- Process temperature up to 100 °C,process pressure up to 10 bar

- 3 in 1: combines display, analog output (according to NAMUR NE 43), and binary output

- High enclosure rating of IP 67, rotatable housing and remote amplifier

- IO-Link 1.1

LFV200

The intelligent limit switch for all kinds of liquids

- Commissioning without container filling or medium calibration

- Immune to deposit formation

- Process temperature up to 150 °C

- Two electrical output versions and IO-Link available

- Pipe extension up to 1,200 mm

- Hygienic designs with polished surface, CIP- and SIP-capable

- Housing made of 316L stainless steel

- Very high repeatability

UP56

Tough, non-contact, pressure-resistant

- Non-contact measurement up to 3.4 m operating distance / 8.0 m scanning distance limit

- Pressure resistant up to 6 bar

- Converter protected by PVDF cover for increased resistance

- 3-in-1: Continuous measurement, switching signal, and display

- Analog output can be switched 4 mA … 20 mA and 0 V … 10 V

- Process connector thread G 1 and G 2

- IP67 enclosure rating

- Simple operation, also via Connect+

LBV301

Rugged, flexible and cleanable

- Compact sensor from 1 thread

- Monoprobe design prevents bulk materials from sticking or jamming

- Polished monoprobe for food applications

- Commissioning without filling and medium calibration

- Process temperature up to 250 °C

- ATEX certifications (1D/2D/1G/2G) available

- Tube extension variant (LBV331) up to 6 m and cable extension model (LBV321) up to 80 m available for vertical mounting

GRF18S

Easy, compact and rugged

- Rugged fill level measurement in fluid media

- Small, compact design; no medium calibration required

- Process temperature up to 55 °C, process pressure up to 16 bar

- IP 67 and IP 69 enclosure rating

- Process connection G ½

- Highly medium resistant due to stainless steel housing 1.4404, polysulfone apex

- Output available as PNP or NPN transistor

- FDA compliant, UL

LFC

Flexible and straightforward point level measurement – the economic solution

- Capacitive level switch based on electrical impedance spectroscopy

- Plug and play: preset to watery media

- Process temperature: −20 °C … +100 °C (+135 °C for 1 h)

- Process pressure: −1 bar … +25 bar

- Two digital PNP outputs with IO-Link 1.1

- Enclosure ratings IP66, IP67 and IP69

- Ideal for hygienic applications (easy to clean, EHEDG, 3A, EG1935/2004, FDA, CIP- and SIP-capable, hygienic adapter available)

LFV300

Flexible and robust – Tuning Forks for all kinds of liquids

- Choice of various housing materials and electrical output signals

- Commissioning without filling

- Process temperature up to 250 °C

- Immune to deposit formation

- Very high repeatability

- Hygienic designs according to EHEDG and FDA, compatible for CIP and SIP

- ATEX approval available

- Tube extension up to 6 m in length

LBV300

Tuning forks – tough and flexible in bulk

Solids

- Tough device design

- Several housing materials and electrical outputs available

- Immune to deposit formation

- Commissioning without filling

- Process temperature up to 250 °C

- Very high repeatability

- ATEX versions (1D/2D/1G/2G) available

- Tube-extended version (LBV330) up to 6 m and rope extensions version (LBV320) up to 80 m available for vertical mounting

CFP Cubic

Multifunctional sensor for level and temperature measurement

- Continuous level measurement and temperature measurement as well as level and temperature switches

- Measurement irrespective of container material

- Probe from 100 mm to 1,000 mm

- Display and intuitive menu navigation

- No mechanical moving parts

- IP 67 enclosure rating and IO-Link 1.1

- No dead zone along the measuring range

Speak with a Dedicated CIMTEC Representative

CIMTEC has developed an extensive product offering through partnerships with industry leading manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.

Need to speak with someone immediately?

Call us at

877.524.6832