Linear Encoders

Linear encoders detect linear movements as absolute position values without making contact. No reference run is required for the wear- and maintenance-free encoders. Different constructions with high resolution and rugged design enable use in a wide range of applications and industries.

EcoLine

Modular wire draw encoder in miniature design

- Measuring lengths: 1.25 m … 10 m

- Modular measuring system with a wide selection of interfaces/measuring lengths

- Very small, slim housing (55 mm … 190 mm) with spring integrated in the measurement drum

- Light yet shock-proof and temperature-resistant plastic housing

- Analog interface with teach-in function on encoder

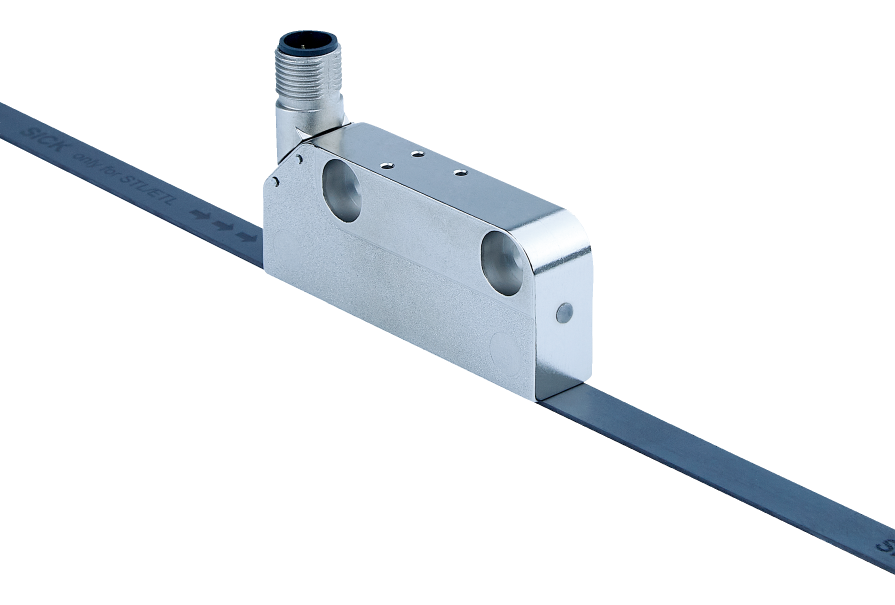

STL/ETL70

Ultra high speed measurement for linear direct drives

- Absolute measurement system for linear direct drives

- Measuring lengths: up to 16,384 mm

- High traversing speeds: up to 10 m/s

- Status LED

- Non-contact measurement system; reading distance to the magnetic tape: up to 0.8 mm

- Electronic type label

- ETL70 with one cable technology thanks to the HIPERFACE DSL® interface

- STL70 with HIPERFACE® interface

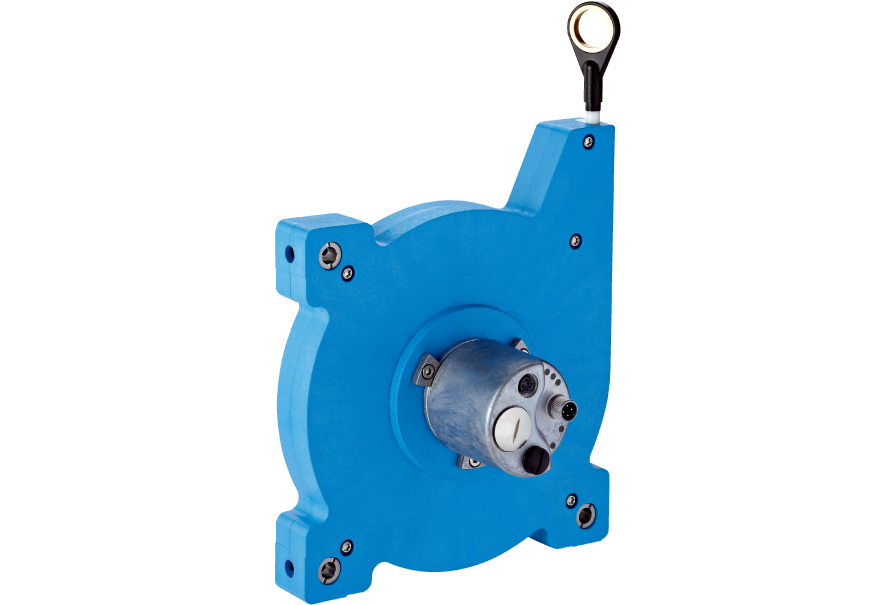

Compact

Compact design – with integrated encoder

- Measuring lengths from 2 m … 5 m

- Integrated measuring system

- Compact housing (90 mm x 90 mm x 90 mm)

- Incremental and absolute versions

- High resolution

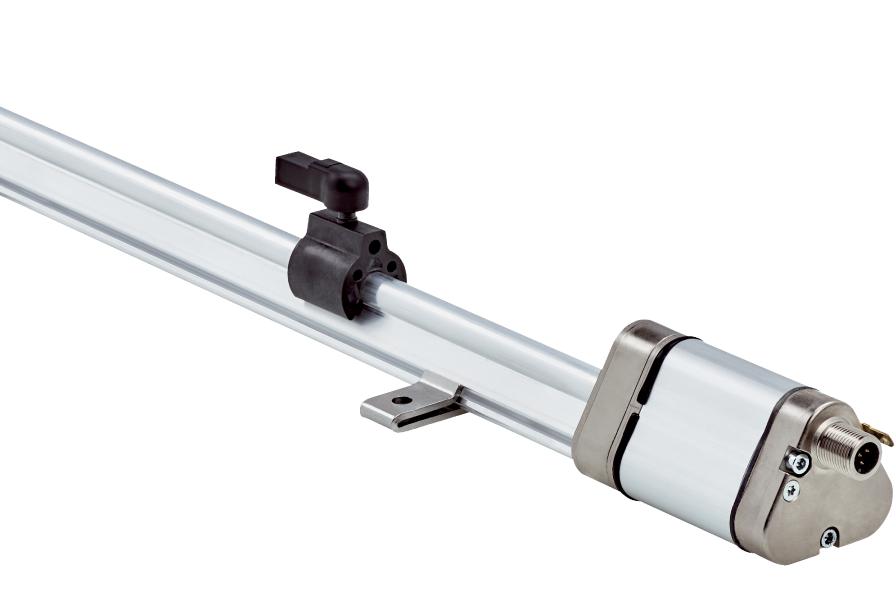

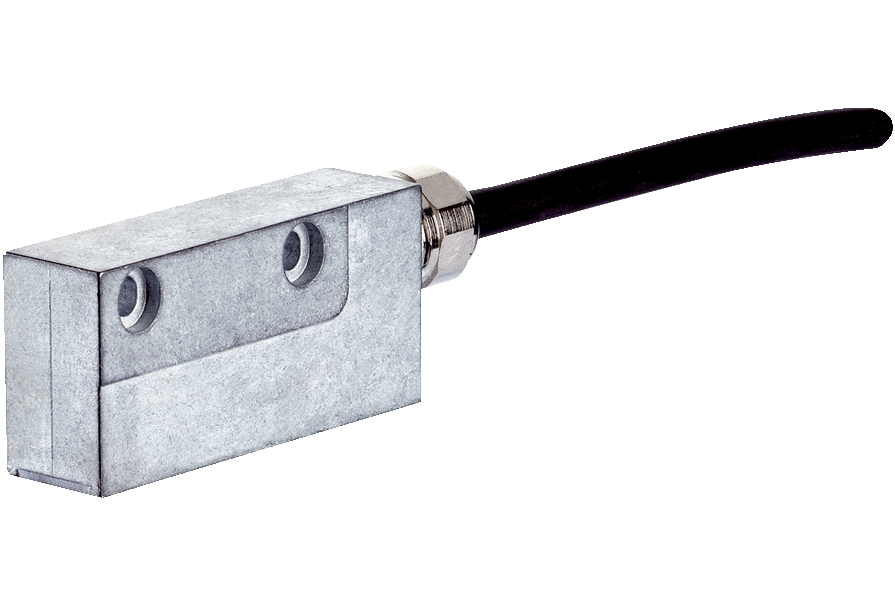

DAX

Flexible linear encoder for countless industrial applications

- Magnetostrictive principle of operation

- Absolute position feedback

- Resolution: up to 10 μm

- Measuring lengths: 50 mm to 2,500 mm

- Available interfaces: Analog and CANopen

- Highly-flexible system architecture

- Intelligent diagnostic functions and condition monitoring

- Profile and hydraulic variants for many installation situations

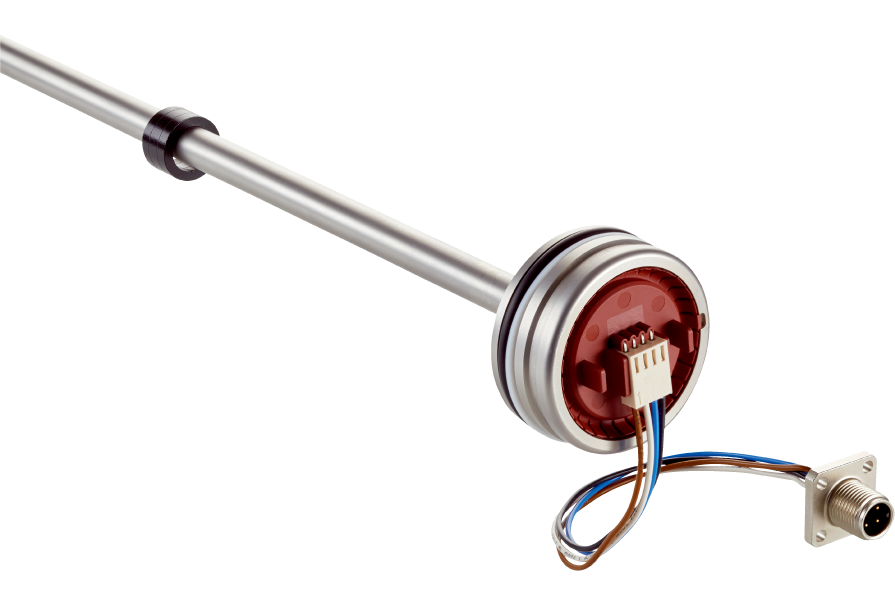

MAX

Integrated cylinder position measurement for mobile machines

- Measuring range: 50 to 2,500 mm (for MAX48N and MAX48A) or 1,500 (for MAX30N), 1 mm increments, typical resolution 0.1 mm

- Analog, CANopen, SAE J1939 and PWM interfaces are available

- Pressure-resistant housing, designed for hydraulic operating pressures of up to 400 bar

- High operating temperature (electronics) up to +105 °C

- Fluid temperature (hydraulic oil) up to max. +95 °C

- Compact dimensions: 10 mm installation space, 30 mm cushion zone

- Position magnet does not need a spacer disk

TTK50

Top-speed measurement for linear motors

- Absolute, non-contact, wear-free length measurement system for linear motors

- Measured lengths of up to 1 m

- Suitable for high traverse speeds of up to 10 m/s

- Reliable location positioning even in the event of condensation and contamination of the magnetic tape

- Electronic type label and programming of the position value

- Absolute location positioning, no reference run

- HIPERFACE® interface

- Certified according to SIL2 and PL d

KH53

For the harshest conditions – the heavy-duty linear encoder

- Non-contact length measurement – maintenance-free, rugged, long service life

- High reproducibility (0.3 mm / 1 mm), high system resolution (0.1 mm)

- SSI and PROFIBUS interfaces

- Determination of absolute position

- Measuring lengths of up to 1,700 m possible

- Can be used in harshest ambient conditions

- High traversing speeds of up to 6.6 m/s

- Distance tolerance between read head and measuring element: up to 55 mm ± 20 mm possible

TTK70

Rugged, flexible and cleanable

- Compact sensor from 1 thread

- Monoprobe design prevents bulk materials from sticking or jamming

- Polished monoprobe for food applications

- Commissioning without filling and medium calibration

- Process temperature up to 250 °C

- ATEX certifications (1D/2D/1G/2G) available

- Tube extension variant (LBV331) up to 6 m and cable extension model (LBV321) up to 80 m available for vertical mounting

GRF18S

Easy, compact and rugged

- Rugged fill level measurement in fluid media

- Small, compact design; no medium calibration required

- Process temperature up to 55 °C, process pressure up to 16 bar

- IP 67 and IP 69 enclosure rating

- Process connection G ½

- Highly medium resistant due to stainless steel housing 1.4404, polysulfone apex

- Output available as PNP or NPN transistor

- FDA compliant, UL

LFC

Flexible and straightforward point level measurement – the economic solution

- Capacitive level switch based on electrical impedance spectroscopy

- Plug and play: preset to watery media

- Process temperature: −20 °C … +100 °C (+135 °C for 1 h)

- Process pressure: −1 bar … +25 bar

- Two digital PNP outputs with IO-Link 1.1

- Enclosure ratings IP66, IP67 and IP69

- Ideal for hygienic applications (easy to clean, EHEDG, 3A, EG1935/2004, FDA, CIP- and SIP-capable, hygienic adapter available)

LFV300

Flexible and robust – Tuning Forks for all kinds of liquids

- Choice of various housing materials and electrical output signals

- Commissioning without filling

- Process temperature up to 250 °C

- Immune to deposit formation

- Very high repeatability

- Hygienic designs according to EHEDG and FDA, compatible for CIP and SIP

- ATEX approval available

- Tube extension up to 6 m in length

LBV300

Tuning forks – tough and flexible in bulk

Solids

- Tough device design

- Several housing materials and electrical outputs available

- Immune to deposit formation

- Commissioning without filling

- Process temperature up to 250 °C

- Very high repeatability

- ATEX versions (1D/2D/1G/2G) available

- Tube-extended version (LBV330) up to 6 m and rope extensions version (LBV320) up to 80 m available for vertical mounting

CFP Cubic

Multifunctional sensor for level and temperature measurement

- Continuous level measurement and temperature measurement as well as level and temperature switches

- Measurement irrespective of container material

- Probe from 100 mm to 1,000 mm

- Display and intuitive menu navigation

- No mechanical moving parts

- IP 67 enclosure rating and IO-Link 1.1

- No dead zone along the measuring range

Speak with a Dedicated CIMTEC Representative

CIMTEC has developed an extensive product offering through partnerships with industry leading manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.

Need to speak with someone immediately?

Call us at

877.524.6832