Machine vision illumination creates contrast between the object features to be detected in an inspection application. We offer a variety of lighting types and techniques for capturing the test object and its material properties.

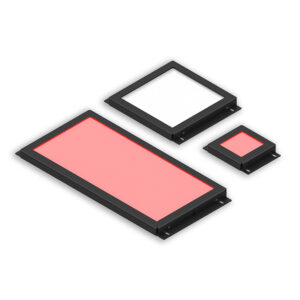

Backlights

Backlighting provides an area of uniform illumination, oriented behind the object of interest, primarily for creating a part silhouette of instant contrast between dark and light. It is most useful for edge detection, part location/orientation or presence/absence, hole detection and object gauging. Linear Backlights can also be deployed behind a moving web of material when used in conjunction with line scan cameras, when intensities are enough to freeze motion.

Bar Lights

Bar Lights, also known as Linear Array Lights, offer both bright field and dark field illumination, depending on angle of incidence with respect to the object of interest. Because of the variety of lengths available, bar lights are useful for large area illumination when used in opposing pairs or in a picture frame mounting orientation. Bar Lights can also be used in replacement of Spot or Ring Lights when greater intensity is required.

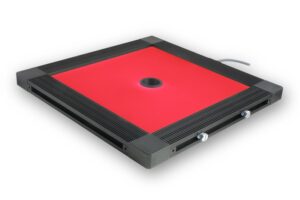

Coaxial Lights

Coaxial Lights provide a type of diffuse illumination, generated from an internal source. The light is then deflected downward onto the imaging plane via a 50% beamsplitter, which also allows light from the object to be collected by the camera above. Ideal for imaging highly reflective objects or where the area of inspection is obscured by shadows from its surroundings. The result of this illumination type is to apply a sheet of light to the object from above and collect the result of how the light is reflected, scattered or absorbed.

Diffuse Lights

Machine vision dome lights provide diffuse lighting, also known as “cloudy-day illumination”. Reflected light provides non-directional, soft illumination that is free of shadowing. This effect is well suited for inspecting highly specular, and curved objects, but at close working distances. The light I.D. needs to be approximately 50% oversized compared with the object size to be illuminated.

Line Lights

LED Line Lights, as opposed to linear array bar lights, employ a secondary lens to focus the light into a narrow beam, typically for short to intermediate working distances, and are mostly used in conjunction with line scan cameras. Line lights are typically mounted in a medium to high angle bright field orientation, but may also be mounted in medium angle dark field. As with any line scan application involving moving surfaces, the lights must have sufficient intensity to freeze motion.

Ring Lights-Dark Field

Dark Field Lights provide illumination that is projected at a shallow angle to the imaging surface, 45 degrees or less. Typical applications include reflective flat surface defect or edge detection, where the majority of the light may reflect away from the camera on the flat, featureless surface but defects may scatter the light to the camera, creating feature appropriate contrast. Dark Field Lights can be dedicated ring lights, or any general bar or spot light oriented at low angles of incidence, depending on defect orientation. Very low angle dark field ring lights must be deployed at close working distances to be effective.

Ring Lights-Bright Field

Bright Field Lights provide illumination directly onto an object, at angles of incidence above 45 degrees from horizontal, creating distinct shadows or general purpose illumination depending on subjects features.. This type of lighting is effective when used on objects requiring high degrees of contrast, but may create unwanted specular reflections when directed at shiny or reflective materials because of the high angle of incidence. Working distances can be short to very long.

Spot Lights

Spot Lights are typically characterized as general-purpose illuminators. They may be used to create both bright field and dark field effects, depending on the light angle of incidence. Working distances for inspection Spot Lights can be short to long, depending on available intensity and beam spread. Small spot lights are beneficial when deployed in tight spaces.

Speak with a Dedicated CIMTEC Representative

CIMTEC has developed an extensive product offering through partnerships with industry leading manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.

Need to speak with someone immediately?

Call us at

877.524.6832