Astrocyte Deep Learning Software

No-Code AI training tool to quickly deploy AI models for machine vision solutions

Teledyne DALSA Astrocyte empowers users to harness their own images of products, samples, and defects to train neural networks to perform a variety of tasks such as anomaly detection, classification, object detection, and segmentation. With its highly flexible graphical user interface, Astrocyte allows visualizing and interpreting models for performance/accuracy as well as exporting these models to files that are ready for runtime in Teledyne DALSA Sapera and Sherlock vision software platforms.

Why AI?

Traditional Machine Vision Tools

- Confuse water droplets and surface damage

- Can’t handle shade and perspective changes

- Miss subtle surface damage

AI Classification Algorithm

- Ignores water droplets

- Is robust to variations in surface finish and perspective

- Can detect a full range of defects

No AI expertise or code required

- Train a model without having to learn about any AI parameters

- Simply choose one of three tuning depth options (low, medium, high), and easily get an optimized AI model

- Graphical user interface for rapid machine vision development

- Train AI models quickly (under 10 minutes with good data)

Save time labelling images and training

- Continual learning allows for updating of classification models on the factory floor without retraining. This saves hours of time updating models.

- Automatic labelling (Via SSOD or pretrained models) generates bounding boxes and labels

- Import existing label sets (.txt, PASCAL VOC, MS COCO, KITTI))

- Segmentation annotation with different shapes (polygon, rectangle, circle, torus tools)

- Decrease training effort with pre-trained AI models (less samples required)

Combine with other Teledyne components

- Leverage Teledyne’s Sherlock or Sapera Processing to get the best of rule-based algorithms combined with AI models for a full solution

- Live video acquisition from Teledyne and third-party cameras

Key Features

- Graphical User Interface for rapid machine vision application development.

- Automatic tuning of training hyperparameters for maximum ease-of-use for non-experts in AI (also a manual mode for experts)

- Automatic generation of annotations via pre-trained models or semi-supervised training

- Masking of regions to exclude from inspection via ROI markers of multiple shapes.

- Highly accelerated inference engine for optimal runtime speed on either GPU or CPU

- Training on multiple GPUs to reduce training time.

- Continual Learning (aka Lifelong Learning) in classification for further learning at runtime.

- Object detection at an angle (aka rotated bounding boxes).

- Location of small defects in high-resolution images via tiling mechanism.

- Easy integration with Sapera Processing and Sherlock vision software for runtime inference.

- Assess AI models via visual tools such as heatmaps, loss function curves, confusion matrix.

- Full image data privacy – train and deploy AI models on local PC.

Application Examples

Astrocyte to Inspect Shredded Plastic Particles in Recycling Industry

Plastic particles, such as from beverage bottles, undergo a multiple-step recycling and inspection process before they are reused in new plastic products. Astrocyte is used to locate and classify more than 30 types of materials with high accuracy to ensure high quality material with less than 10 parts per million of contaminants.

Astrocyte significantly improves quality, productivity, and efficiency in X-ray medical imaging

The tiny and random nature of fibers on X-ray detectors make them challenging and time consuming for traditional methods or humans. With Astrocyte, the X-ray solutions team was able to rapidly identify all defects and even outperform their operators.

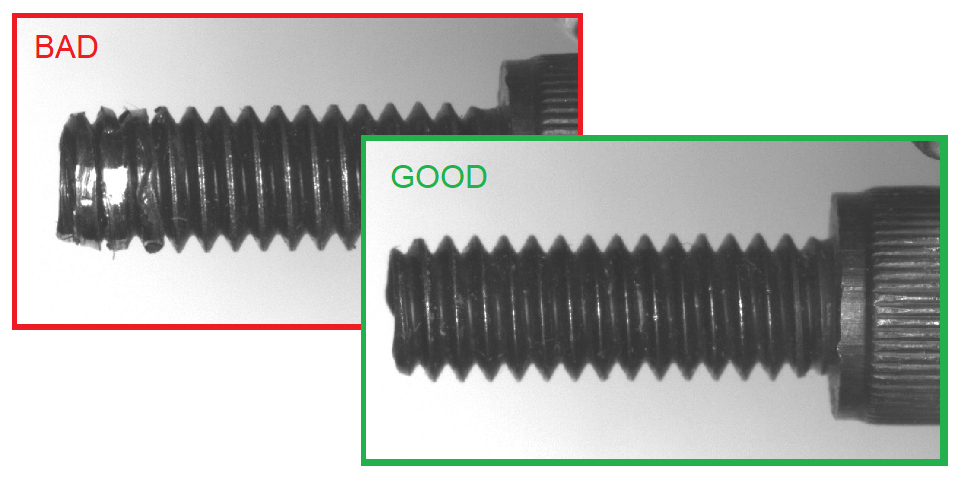

Inspection of screw threads

Classification of good and bad screw tips. Subtle defects on screw threads are detected and classified as bad samples. Astrocyte detects small defects on high resolution images of reflective surface. Just a few tens of samples are required to train a good accuracy model. Classification is used when good and bad samples are available, while Anomaly Detection is used when only good samples are available.

Location/identification of wood knots

Localization and classification of various types of knots in wood planks. Astrocyte can robustly locate and classify small knots 10-pixels wide in high-resolution images of 2800 x 1024 using the tiling mechanism which preserves native resolution.

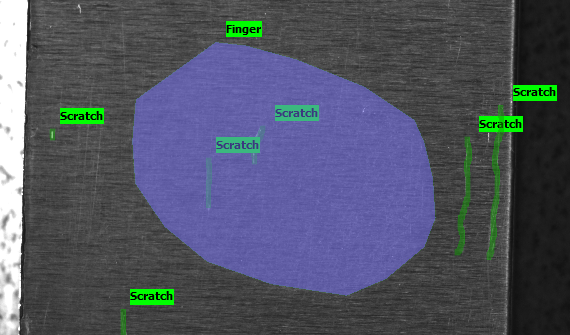

Surface inspection of metal plates

Detection and segmentation of various types of defects (such as scratches and fingerprints) on brushed metal plates. Astrocyte provides output shapes where each pixel is assigned a class. Usage of blob tool on the segmentation output allows performing shape analysis on the defects.

Deep Learning Architectures

Astrocyte supports the following deep learning architectures.

Classification

Description

A generic classifier to identify the class of an image.

Typical Usage

Use in applications where multiple class identification is required. For example, it can be used to identify several classes of defects in industrial inspection. It can train in the field using continual learning.

Anomaly Detection

Description

A binary classifier (good/bad) trained on “good” images only.

Typical Usage

Use in defect inspection where simply finding defects is sufficient (no need to classify defects). Useful on imbalanced datasets where many “good” images and a few “bad” images are available. Does not require manual graphical annotations and very practical on large datasets.

Object Detection

Description

An all-in-one localizer and classifier. Object detection finds the location and the orientation of an object in an image and classifies it.

Typical Usage

Use in applications where the position and orientation of objects is important. For example, it can be used to provide the location and class of defects in industrial inspection.

Segmentation

Description

A pixel-wise classifier. Segmentation associates each image pixel with a class. Connected pixels of the same class create identifiable regions in the image.

Typical Usage

Use in applications where the size and/or shape of objects are required. For example, it can be used to provide location, class, and shape of defects in industrial inspection.

Speak with a Dedicated CIMTEC Representative

CIMTEC has developed an extensive product offering through partnerships with industry leading manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.

Need to speak with someone immediately?

Call us at

877.524.6832