SICK

SICK Safety Systems Help Manufacturers Improve Workplace Safety and Reduce Injuries

Operator safety is a key factor in the design and operation of any manufacturing facility. SICK develops a line of safety sensors and control systems to prevent operator injury for a wide range of manufacturing scenarios.

Just about every manufacturing plant has to conform to a variety of safety rules and regulatory requirements. SICK sensors and control systems help manufacturing plant owners to create a safe environment for their machine operators and to conform to relevant rules and regulations. SICK has been producing top of the line sensors and control systems for over fifty years, making them the industry leader in manufacturing safety systems.

Safety Camera Systems

SICK’s safety camera systems use video imaging to detect intrusion into a hazardous point in a work station. These safety cameras can be installed in semi-automatic work stations, test, assembly and inspection stations, service openings with sporadic access, and general presence detection. SICK’s safety cameras can be used to monitor rectangular planes of nearly any size using the same model camera, and only one component is needed per location, reducing the number of different models needed by a facility.

For example, safety camera systems can be installed on semi-automatic assembly cells where robots perform the majority of an assembly task, but rely on human operators for some tasks. The SICK safety camera system monitors the entry plane of the cell, detecting when the operator reaches into the cell. The safety system stops the movement of the robotic arm, preventing potential injuries to the operator by the robotic arm or its tools.

Light Curtains

Light curtains are sensors that monitor a plane within the workspace for intrusions. Intrusions can include a hand entering a workspace or an operator entering a work cell. Each light curtain sensor contains a number of light beams arranged in parallel to provide constant monitoring of intrusions anywhere in the plane. SICK’s light curtain sensors can be programmed to accept certain types of intrusions, such as raw materials entering a tool, while halting operations when a non-acceptable intrusion is detected.

Light curtains can be installed on machine tools such as hydraulic brakes and presses to provide hand safety to operators. Light curtains can also be installed on the entrance to robotic work stations to enable the robot to halt or modify its operational envelope if an operator enters the work cell.

Laser Scanners

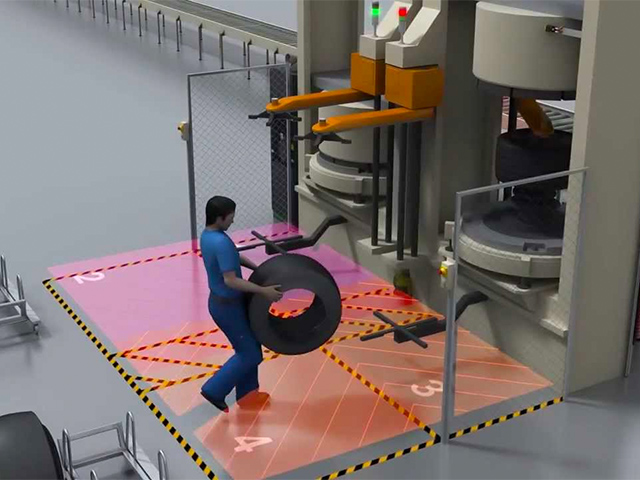

Laser scanners, like light curtains, monitor a plane within the workspace for intrusions. However, the laser scanner operates radially from a unit mounted at a single point, rather than a parallel series of sensor elements, as in the light curtain. Laser scanners use a laser beam to scan an area in front of the sensor, and can detect objects that enter the range of the sensor. SICK laser scanners can be programmed to provide warnings when an object enters an initial range, and can shut down system operations when an object enters a critical range. Like SICK’s light curtains, their laser scanners can also be programmed to accept specific intrusions such as products on an assembly line that meet a certain shape profile. In addition to these applications, SICK laser scanners can be mounted on mobile motorized systems or tracked vehicles to provide proximity sensing functions.

For example, high-bay pallet storage systems can use SICK laser scanners to detect which bays in the storage rack are occupied with pallets and which are empty, allowing the system to move pallets into the empty bays.

All of SICK’s sensor products can be integrated into a complete safety protection scheme for a variety of manufacturing applications.